Home Facility

Altech Automotive is located in the Industrial Area of Greater Noida which is just 20 miles from the national capital New Delhi. The city of Greater Noida is well known for great infrastructure with several Fortune 500 companies located in the area.

Altech Automotive is equipped with Cold chamber Die Casting Machines ranging from 180 tons to 1000 tons that have been imported from Taiwan, Switzerland, and Italy. Currently, we have an installed capacity to produce 1500 tonnes of castings annually. As our responsibility towards protecting the environment, all our melting furnaces are electrically heated. Use of any furnace oil or High speed Diesel for melting of aluminum alloys is prohibited in our facility.

Altech Automotive has more than 20 CNC machines (10 horizontal turning machines and 10 Vertical Machining Centers) which are used in finishing of Aluminum Castings and Steel forgings. To provide top quality to customers, all drill tap operations on castings and steel forgings are done on machines imported from USA and Japan. We also have in-house facilities for Tool Designing & Tool manufacturing.

De-burring is done by skilled operators using files and by use of on Lapping & Buffing Machines. In addition we have a Shot Blasting machine in-house which is used to improve the surface finish of castings before powder coating as required by customers.

| 1000 Ton | 1 | TRILUZI |

| 668 Ton | 1 | LANSON |

| 420 Ton | 1 | ZITAI |

| 250 Ton | 1 | BUHLER/HMT |

| 180 Ton | 2 | BUHLER/HMT |

| VMC | 10 (BROTHER / FANUC / HAAS) |

| Turning Centre | 10 (LMW/ACE) |

| Solidworks 2016 | 2 | Stations |

| Auto CAD | 2 | Stations |

| Delcam | 1 | Station |

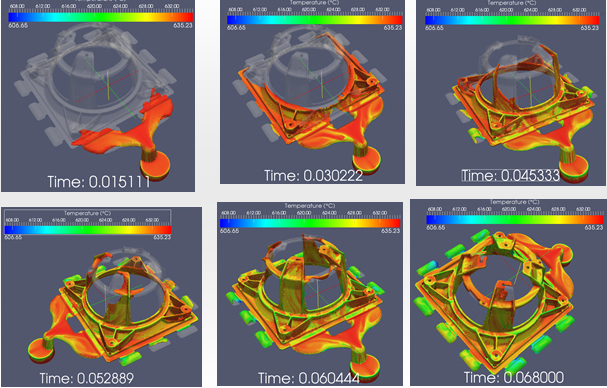

| Flow Analysis Software | 1 | Station |

| CNC VMC | 3 | HAAS |

| E.D.M | 1 | SPARKONIX |

| Milling M/C | 3 | KENT/PACMILL |

| Lathe M/C | 5 | HMT |

| Hyd.Surf.Grinder | 2 | RAMANNA |

| Rad.Drill M/c | 2 | PACMILL |